rubber slurry pump parts suppliers

Latest articles

>Dredge Pump

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreIs the discharge configuration suitable for abrasive slurries?

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreHow to Succeed in Slurry Pumping?

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreMaterials of Construction

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreThese conditions include

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreAlthough the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

rubber slurry pump parts suppliers...

rubber slurry pump parts suppliers 【rubber slurry pump parts suppliers】

Read More

Popular articles

- Choosing The Right Slurry Pump For Your Application

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

- Abrasive.

- How does a dredge pump work?

- Slurry Pump Impeller Type

- High head (i.e. the height to which the pump can move the liquid)

Latest articles

-

>Dredge Pump

-

Underwater installation

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

Slurry Pump VS Mud Pump

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

iron frying pan. They need to be dried thoroughly after washing to prevent rusting and periodically reseasoned to maintain their non-stick properties. Despite this, their durability is unparalleled. With proper care, an iron frying pan can last generations, passed down from one cook to the next.

iron frying pan. They need to be dried thoroughly after washing to prevent rusting and periodically reseasoned to maintain their non-stick properties. Despite this, their durability is unparalleled. With proper care, an iron frying pan can last generations, passed down from one cook to the next.Use a clean paper or lint-free towel to wipe out any excess oil and grease. Wash the pan with warm water and a soft-bristle brush or a non-scouring sponge. For stuck-on food, fill the pan with just enough water to cover the bottom and let it simmer for 3 to 5 minutes. Allow the pan to cool and then scrape the food off with a spatula. Immediately dry the pan with a paper or lint-free towel and then evenly rub a light layer of cooking oil onto the pan.

Lightweight, easy to maneuver, and with unrivaled heat control, the advantages of stainless steel pans make these an absolute staple in any kitchen.

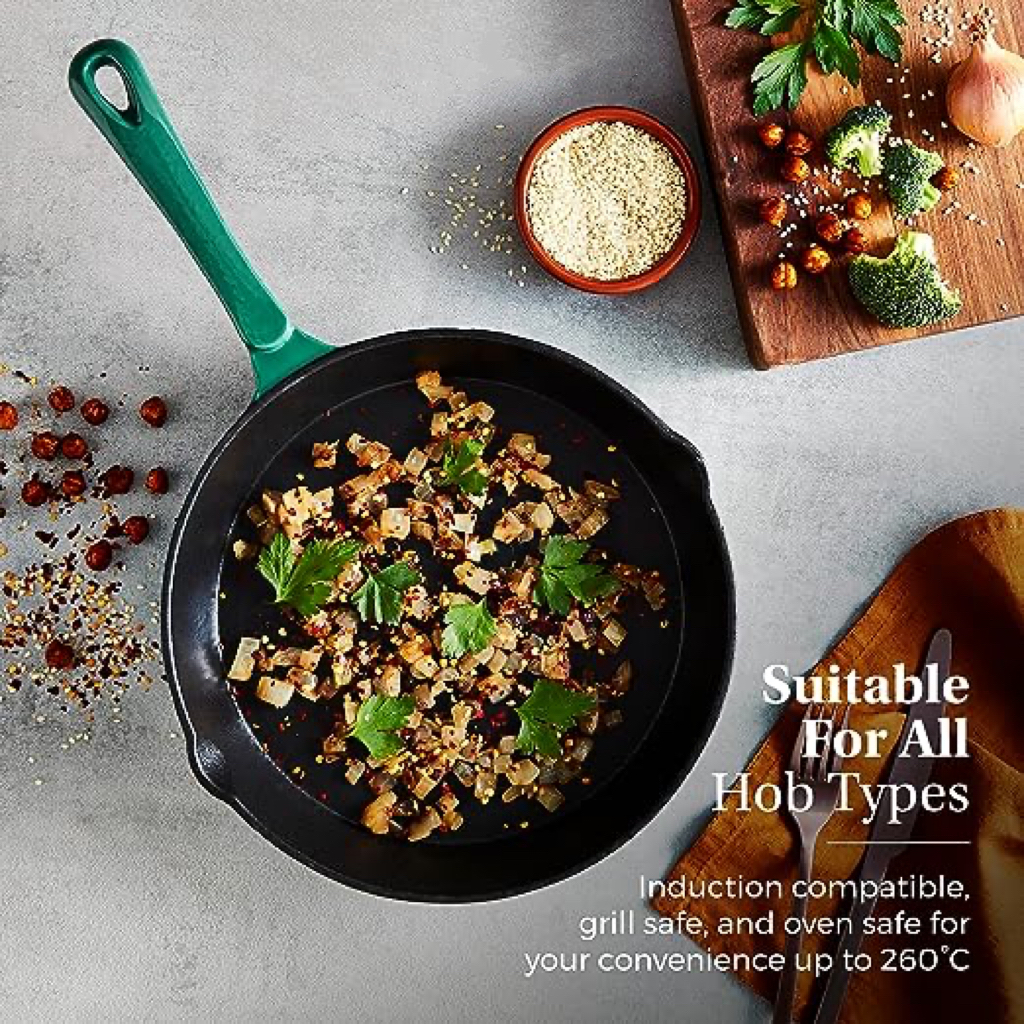

The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots

The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots The enamel grill pan is specifically designed to work in tandem with this technology, guaranteeing rapid and even heating without hotspots enamel induction grill pan. Whether you're searing a steak or gently sautéing vegetables, the consistent heat will help you achieve perfect results every time.

enamel induction grill pan. Whether you're searing a steak or gently sautéing vegetables, the consistent heat will help you achieve perfect results every time.

Cooking meat, fish, and vegetables on a cast iron pan have a rustic beauty all its own. The sear marks added flavor to the dish and the natural smoking of the seasoned pan adds excitement to using a cast-iron skillet. This makes the skillet pan a must-have pan for each aspiring chef. They are also exceptionally long-lasting, lasting for many years.

The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors

The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors skillet cooking.

skillet cooking.

Choose Enamel-coated Cast Iron Cookware

Frying pans or skillets have flat bottoms, flared sides, a shallow depth, and no lids. These features make them the perfect choice for shallow frying, flipping food, stirring, high-heat searing, or grilling meat at high temperatures.

two sided griddle. The flat side of the griddle is perfect for cooking foods that need to be cooked evenly, such as pancakes or eggs. The ridged side, on the other hand, is great for grilling meats and creating those coveted grill marks. By being able to adjust the heat on each side independently, you can ensure that your food is cooked to perfection every time.

Kitchen Cookware Multifunction Rectangular Frying Pan Cast lron Wok

Handle Construction

In the labs, we put the carbon steel pans through the same tests as our cast-iron pans: heating evenness, baking, and browning. You have to keep carbon steel pans seasoned, like cast iron, but if you do, they soon develop a smooth patina that makes a pan as slick as nonstick, giving you even more cooking possibilities.

Skillets are typically deeper than frypans, which makes them more suitable for dishes that call for more liquid or sauce. Its depth also allows you to add in more ingredients for one-pan meals that include vegetables and meat. All this without spilling out.

grill press. When you press down on meats, the juices are forced to stay inside, resulting in a more succulent and flavorful end product. This is especially useful when grilling lean meats that tend to dry out quickly. By using a grill press, you can ensure that your meats stay moist and delicious, no matter how long they cook.